Following our great success with our experiment in which we built a fantastic work space for €44.95 out of recycled and reused materials , I received this comment in my inbox from the Architect Andy Burdon whose brains I pick occasionally specially when I am looking for advice on building regulations or cutting edge green technology. I thought this comment worthy of a blog post…

The problem with self-builders using recycled materials

“A major problem with the proposal to construct an extension constructed from recycled or re-used materials is the legal requirement to comply with statutory requirements, primarily Planning Control and the Building Regulations. Understanding or interpreting these regulations and applying them to a self build construction may be beyond the expertise of aspiring self builders. There are several sources of self-help books or even “Wiki How” web pages that can guide prospective 5Kers through this maze of requirements and regulations.

However, the fundamental problem is how can one be certain the proposed building is compliance with the regulations and is structurally safe and sound? Traditional building techniques such as concrete foundations and block or brickwork walls are sufficiently proven to allow for safe construction , but in your project these components and techniques are likely to be too expensive. Given the budget allowance, alternative construction techniques may be required.

These questions lead inevitably towards the necessity to seek relevant expert advice and guidance, before and during and sometimes even after construction. For the most part , this service can be supplied by a competent Architect or Engineer, however, it is unlikely that this service will be free of charge. With a stated budget limit of €5K, this may be a problem.

The use of second-hand, or re-used components present difficulties in terms of quality control for structural components of any extension. Without independent testing and certainty it is unlikely that a structural engineer would be satisfied with the use of reused components. It must be remembered that any professional involved with the project is taking on a “duty of care” and would be liable if anything were to go awry.

A solution to these impediments may be to employ an Architect/ Engineer/ Supplier/ Fabricator with the skill , training and relevant insurances to design and supervise the installation of a low-budget structural “frame” set onto designed foundations and made of specified components , which can then be safely infilled with floors, walls, windows and a roof formed from reused or recycled materials as required by the aspiring €5Ker. This is a similar, but more site-specific solution than the use of a cargo container cut away to allow for various uses, and it avoids the expensive cost of cranes ! Although a cost will arise for this service, the ability then to proceed re using / recycling materials becomes a viable option providing appropriate materials are used. I believe this option offers great potential and should be further investigated.

Best wishes with the project

Andy Burdon

Thank you Andy, While I recognise the importance of a strictly regulated, compliant construction sector, it does as you say put a huge financial burden on our miniscule budget in terms of affording competent professionals. Your suggestion does however allow us to be creative and experimental insofar as infill material is concerned and attempt to save costs that way.

In this excellent article from selfbuild.ie Dublin architect Tim Lavin weighs up the advantages and disadvantages of tried and tested components such as Timber Frame, SIPs(Structurally Insulated Panels), Insulated concrete Forms (ICF), Glass, Steel and Strawbale to construct the frame. The article outlines construction methods and planning permission for attaching an extension to your house as a self builder. Well worth a read!

We welcome any advice or thoughts that any of you out there might have of how we might work experimentally and creatively within the constraints of our budget and bureaucracy!

They did it in Brighton!

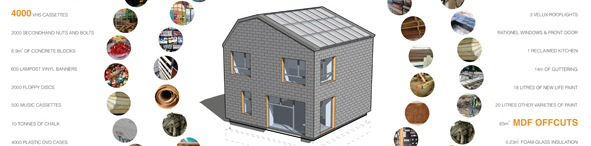

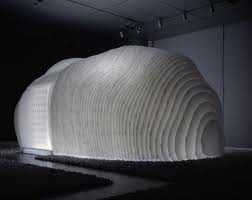

Cast your eyes on these images of The Brighton Waste House, the first permanent building in the UK to be constructed from waste, surplus material and discarded plastics, all under full building regulations and with planning permission!  Two thousand recycled and weatherproof carpet tiles clad the exterior facade while old vinyl banners are used as internal vapor control layers.

Two thousand recycled and weatherproof carpet tiles clad the exterior facade while old vinyl banners are used as internal vapor control layers.  Foundations made from ground-granulated blast-furnace slag support a framework comprising salvaged plywood beams, columns and timber joists rescued from a nearby demolished house.

Foundations made from ground-granulated blast-furnace slag support a framework comprising salvaged plywood beams, columns and timber joists rescued from a nearby demolished house.  Old plastic razors, denim jeans, videocassettes, and 20,000 toothbrushes were inserted into the walls as insulation

Old plastic razors, denim jeans, videocassettes, and 20,000 toothbrushes were inserted into the walls as insulation  To improve energy efficiency and thermal conductivity, the builders constructed rammed earth walls out of chalk waste and clay. Whats more exciting is that the project engages local community and serves as an open research project Find out more about this exciting project by BBM architects here

To improve energy efficiency and thermal conductivity, the builders constructed rammed earth walls out of chalk waste and clay. Whats more exciting is that the project engages local community and serves as an open research project Find out more about this exciting project by BBM architects here

The Plastic House of Lodz, Poland designed by

The Plastic House of Lodz, Poland designed by